- Home

- About Us

- News

-

Recycling Machine

Recycling Machine/Recycling Machine

Specializing in the R&D and production of environmental protection equipment and mining machinery.

- Shredder

- Hammer Mill

- Waste PCB Circuit Board Recycling Equipment

- Waste Wires & Cables Recycling Equipment

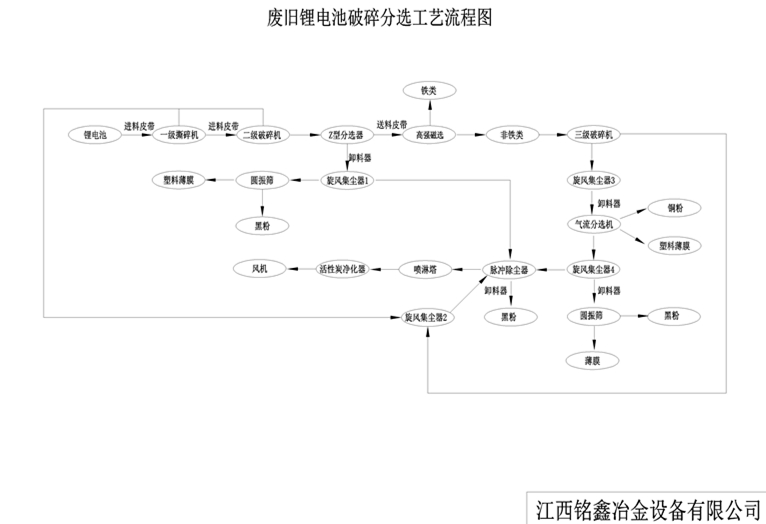

- Waste Battery Recycling Equipment

- Solar Panel Recycling Equipment

- Plastic Recycling Equipment

- Motor Disassembly Equipment

- Home Appliance Dismantling/Recycling Machine

- Dust Removal Equipment

- Scrap Metal Sorting Equipment

-

Mining Machine

Mining machine/Mining Machine

Specializing in the R&D and production of environmental protection equipment and mining machinery.

-

Solution

Solution/Solution

Specializing in the R&D and production of environmental protection equipment and mining machinery.

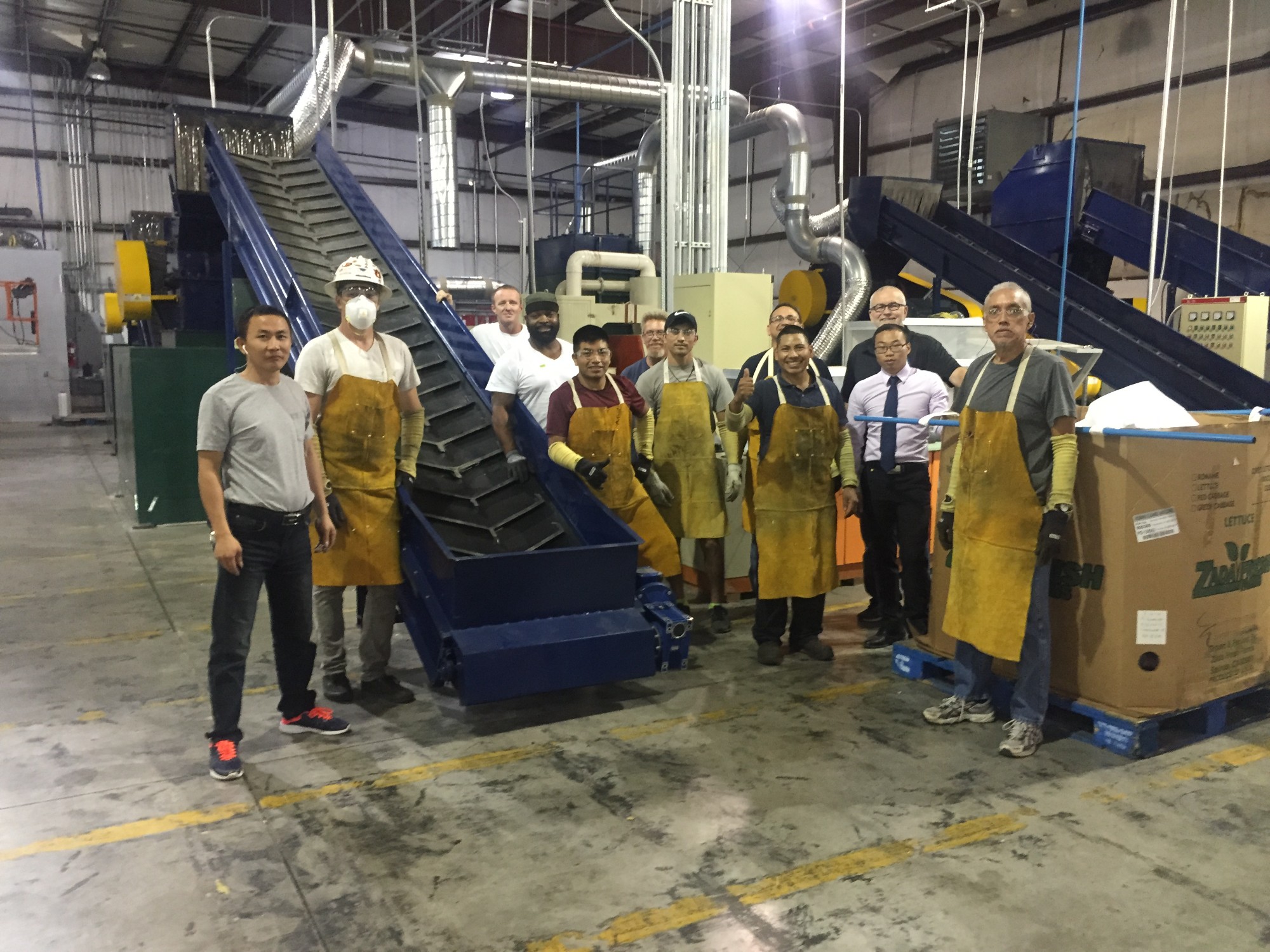

- Case

- Contact