Product Overview

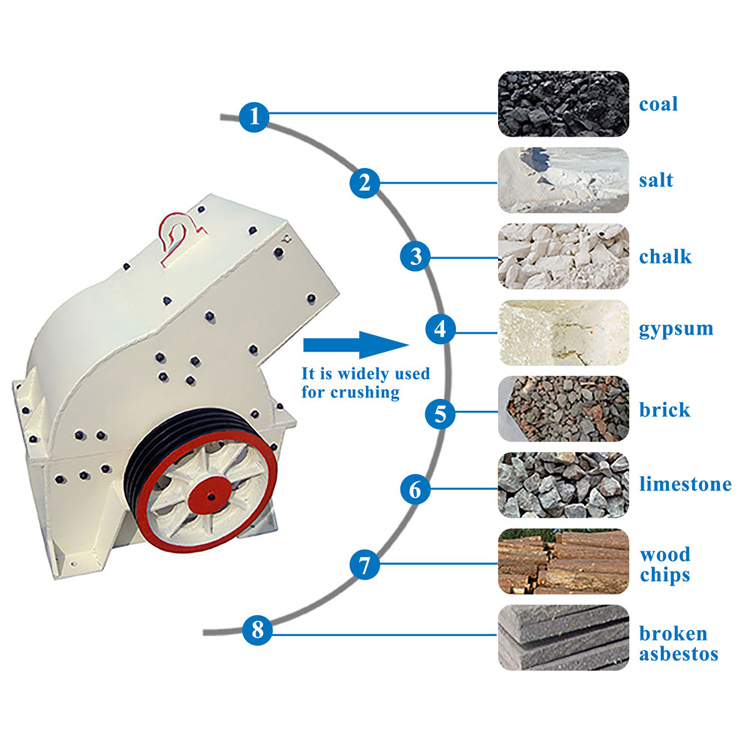

Hammer Crusher is a rock crusher used in various industries to reduce the material size, such as limestone, coal, slags, gypsum, glass. It uses of high-speed rotary hammer to impact the ore, the finished product size is adjustable by controlling the grate openings, rotor speed, hammer capacity, etc. Hammer mill, same as hammer crusher, hammer breaker, can crush the 600-1800 mm materials to below 25 or 25 mm. Sometimes, the hammer mill crusher is named by the application fields, such as coal crusher, coke crusher, limestone hammer crusher, brick crusher, cement hammer crusher, etc.

Product Detail

Structure&Working Principle

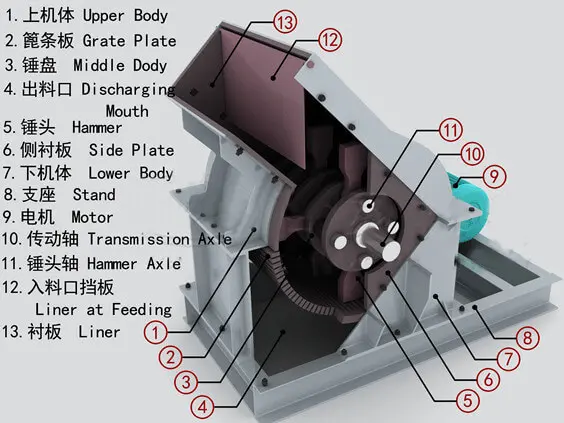

Hammer Crusher Structure

The main parts of a hammer crusher are the crushing chamber, rotor shaft, frame, impact hammer, grate bars, motor, flywheel, grate, pallets and lining, dust seal, and overload protection device.

Hammer Crusher Working Principle

Material is fed into the hammer crusher, which is subject to rotation, high-speed impact, and collision. Qualified crushed ore is discharged through the grate, the larger size materials continue to be crushed and shattered until they reach the required size.

Specification

| Model | Feeding Size (mm) | Discharge Particle Size(mm) | Capacity (t/h) | Power (kw) |

| PCS300*200 | <60 | <10 | 1-2 | 7.5 |

| PCS400*300 | <80 | <10 | 1-3 | 7.5 |

| PC400×300 | <100 | <15 | 3-10 | 11 |

| PC600×400 | <150 | <15 | 10-20 | 22 |

| PC800×600 | <200 | <25 | 20-50 | 55 |

| PC1000*800 | <350 | <35 | 50-70 | 75-90 |

| PC1000×1000 | <350 | <35 | 70-90 | 90-110 |

| PC1200*1200 | <350 | <35 | 80-110 | 132-160 |