Product Overview

The rotary vibrating screen is a vibrating screening equipment with high screening fineness and large processing capacity. It can achieve satisfactory screening results for particles, fine powders, and liquids.

The rotary vibration screen vibrates in a circular motion, with adjustable amplitude, long material screening flow line, multi-layer screening, clear screening of each specification, and high screening efficiency. It is suitable for screening in the mining and sand and gravel industries.

Application Range

- Abrasive & Ceramics: alumina, quartz sand, mud, spray soil particles.

- Chemical: resin sand, pigment, washing powder, micro powder, paint, soda ash, lemon powder, rubber, and plastics.

- Food: sugar, salt, soda, MSG (monosodium glutamate), milk powder, soybean milk, yeast, juice, soy sauce, vinegar, etc.

- Paper Making: coating, coated slurry, black-and-white liquid, waste liquor, papermaking liquid, wastewater recycling.

- Metallurgy: titanium oxide, zinc oxide, electromagnetic materials, metal powder, welding rod powder, titanium oxide, etc.

- Pharmaceutical: TCM (traditional Chinese medicine) powder, TCM liquid, western medical powder, western medical liquid, TCM & western medical particles, etc.

- Environment Protection: rubbish, excrement, waste oil, food effluent, wastewater processing, etc.

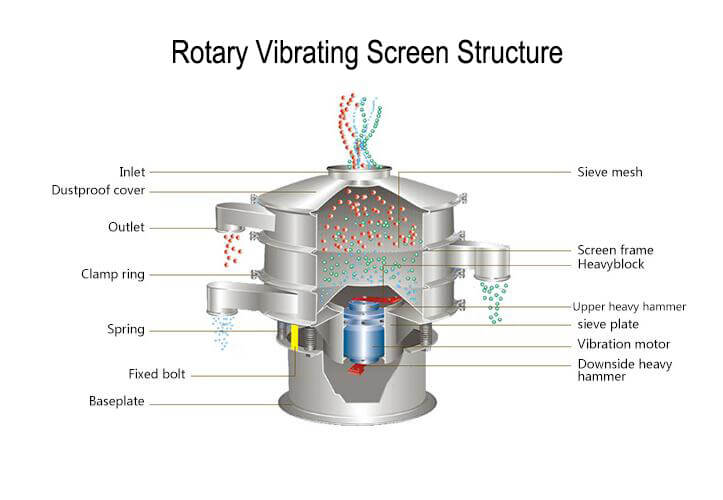

Structure&Working Principle

The rotary vibrating screen uses a vertical vibration motor as the exciter. The upper and lower ends of the vibration motor are equipped with eccentric weights, which convert the rotational motion of the vibration motor into horizontal, vertical, and tilted three-dimensional motion and then transfer this motion to the Screen surface. Adjusting the phase angles of the upper and lower ends can change the movement trajectory of the material on the screen surface.

| Model | Screen Size(m2) | Layer | Screen Diameter(mm) | Screen Mesh (mesh) | Motor Power(kw) |

| Vibration Motor | Ordinary Motor |

| 600 | 0.2281 | 1-5 | 1-25 | Ⴔ540 | 0.55 | 0.75 |

| 800 | 0.4183 | 1-5 | 1-25 | Ⴔ730 | 0.75 | 1.1 |

| 1000 | 0.6359 | 1-5 | 1-25 | Ⴔ900 | 1.1 | 1.5 |

| 1200 | 0.9499 | 1-5 | 1-25 | Ⴔ1100 | 1.5 | 1.5 |

| 1500 | 1.5386 | 1-5 | 5-40 | Ⴔ1400 | 2.2 | 2.2 |

| 1800 | 2.2687 | 1-3 | 5-40 | Ⴔ1700 | 3.0 | 2.2 |

| 2000 | 2.7922 | 1-3 | 1-40 | Ⴔ1886 | 3.7 | 3.0 |