Overview

Solar Plant Recycling is an up and coming waste stream generated in both consumer and commercial fields of use. While demand may not be terribly high at the moment, there are many early-era solar power systems or solar PV systems that will soon be reaching their end of life cycle. MINGXIN stands ready to deliver industry leading end of life management solutions for commercial and consumer solar energy systems.

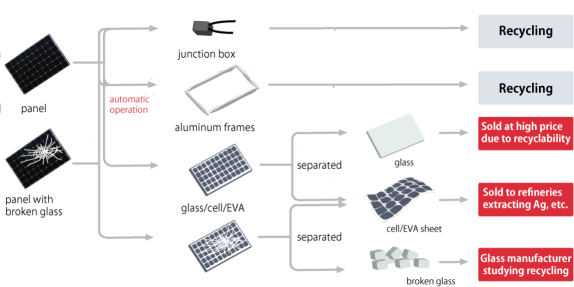

The rest of the components in a solar panel consist of good quality glass, aluminium frames, polymers,silicon, copper and silver paste (used for the printed conductors on each cell), all of which (≥95%), can be successfully recycled.

Recycling Processing

This recycling production line adopts dry process to effectively separate and recycle waste solar panels. The main equipment includes Crushing system, sorting system, dust removal system and so on.

① The frame of the solar panel is removed by the frame removal machine.

② Remove glass on the photovoltaic panel by a glass remover machine.

③ The solar photovoltaic panels with the aluminium frame and glass removed enter the twin shaft shredder. The twin-shaft shredder tears the PV panels into strips. Next, the material enters the crusher. The shredder crushes the material into small pieces of 3-5 cm.

④ Through negative pressure feeding, these small pieces will enter the Fine grinder. The fine grinder we configure is with return material, if the particle size is unqualified, it will be returned to the fine grinder.Qualified sizes enter the air separator.The metal powder is screened out from one side of the air separator. The other side is plastic and a small amount of metal.

⑤ These plastics and a small amount of metal enter the electrostatic separator. The pure plastic and metal are again sorted out.

Final Product