Cyclonic electrolytic technology is an effective method for metal separation and purification, especially suitable for copper electrolysis purification production. This technology can efficiently recover or purify copper from copper electrolytes, while effectively removing impurities such as arsenic, antimony, bismuth, etc., from the solution, avoiding the problem of copper intermediate raw material backlogs, and significantly improving the recovery rate of copper metal products.

Advantages of Cyclonic Electrolytic compared to conventional electrolysis technology

1. Mass transfer efficiency

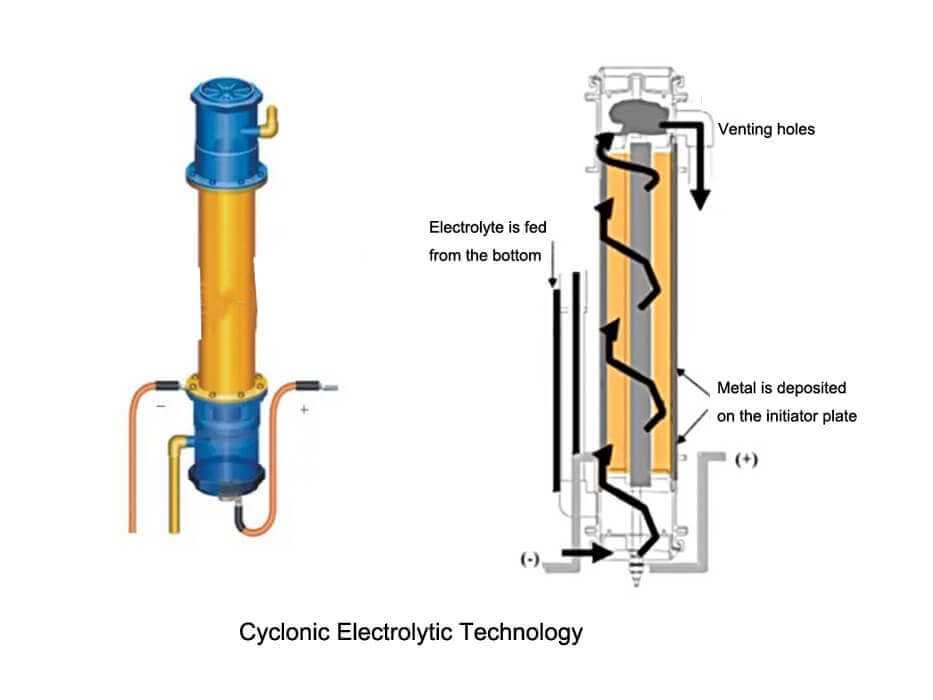

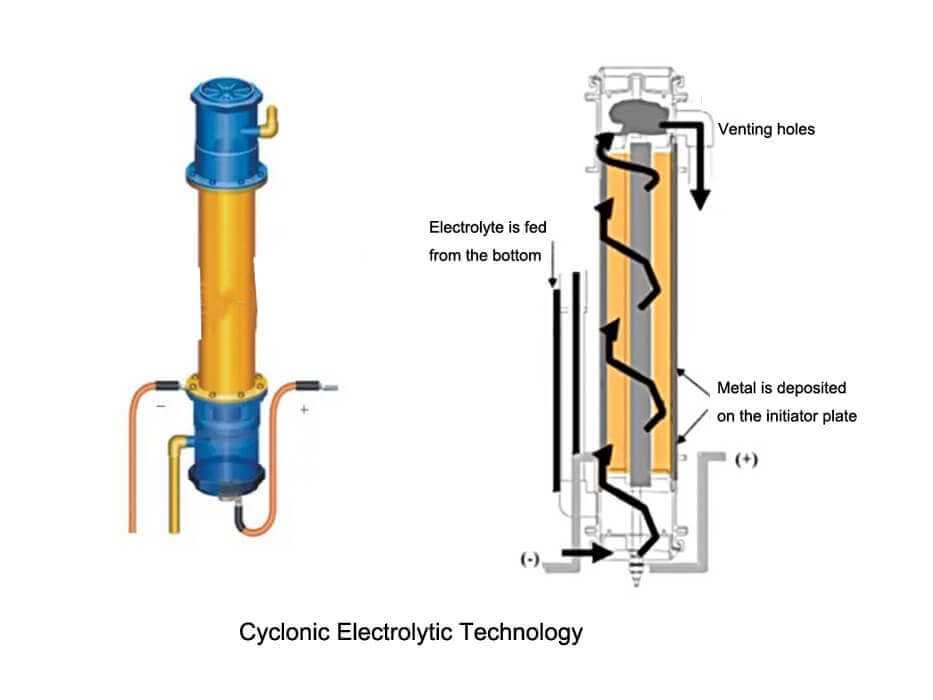

Cyclonicelectrolytictechnology significantly enhances the mass transfer efficiency of metal ions in the electrolyte by introducing cyclonic or eddy current motion. The action of the cyclone reduces the concentration polarization near the electrode surface, allowing the metal ions to reach the electrode surface more quickly, thus accelerating the metal deposition process.

2. Metal Recovery

Cyclonic electrolytic increases the transfer rate of metal ions, which can more easily reach the cathode and be reduced to solid metal. As a result, Cyclonic electrolytes typically achieve higher metal recovery rates, especially when treating low-concentration solutions.

3. Energy Consumption

Cyclonic electrolysis effectively reduces the generation of electrical resistance in the solution, which reduces the concentration polarization at the electrode surface, resulting in a lower overall electrical energy consumption. For the same amount of metal recovered, Cyclonic electrolysis is typically more energy efficient than conventional electrolysis.

Cyclonic electrolytic technology

4. Metal Deposition Quality

Cyclonic Electrolytic Technology: The cyclone motion distributes the metal ions uniformly on the electrode surface, resulting in a denser and flatter layer of deposited metal and reducing the formation of irregular dendrites (dendritic metal structures). This is a great improvement to the purity of the metal and the quality of the final product.

5. Electrolysis speed

Cyclonic motion significantly accelerates metal ions’ mass transfer and reduction process, so the electrolysis speed is faster than that of conventional processes, which can shorten the production cycle.

6. Equipment Design and Space Requirements

Due to the increased mass transfer efficiency and deposition rate, Cyclonic electrolytic technology can be designed to be more compact and efficient for applications where space is limited. Cyclonic electrolytic systems usually require special cyclone generation equipment, but the overall design remains compact.

7. Adaptability

Cyclonic electrolytic technology is particularly effective in recovering metals from low-concentration, complex solutions, and is especially suited for use in complex environments such as electronic scrap, battery recycling, or wastewater treatment. Its high mass transfer capacity makes it possible to maintain good metal recovery results under different conditions.

8. Maintenance and operation

Maintenance may be slightly more complicated due to the relatively complex cyclone design of the equipment, but the advantage of the technology lies in its high efficiency over long periods of operation, reducing the need for frequent cleaning and maintenance.

Cyclonic Electrolytic Copper Recovery System

The cyclonic electrolytic copper recovery system is a technical equipment used for the efficient recovery of copper resources from waste materials, combining two major technologies: cyclone separation and electrolysis refining. The system is mainly used to process copper-containing wastes, such as waste circuit boards, wires and cables, electronic components, etc., aiming at the recovery and purification of copper.

Main Technologies of The System

Cyclone Separation: After the waste is crushed and pulverized, it enters the cyclone. Utilizing centrifugal force, heavier copper particles are separated from lighter impurities (e.g. plastics, rubber, etc.), and copper substances are effectively extracted.

Electrolytic refining: The separated copper particles enter into the electrolytic tank, where the copper ions are reduced to high-purity copper through electrolytic reaction, and the impurities remain in the electrolyte or are deposited as anode sludge, and the pure copper is further extracted.

Advantages

High-efficiency recovery: The system is capable of realizing high-efficiency separation and recovery of copper resources, with a high recovery rate.

High purity: Through the electrolysis process, the final copper purity obtained can reach over 99.99%, which is suitable for high-standard industrial applications.

Environmental protection: The system integrates the treatment of waste gas and wastewater treatment, which reduces environmental pollution and meets environmental protection requirements.

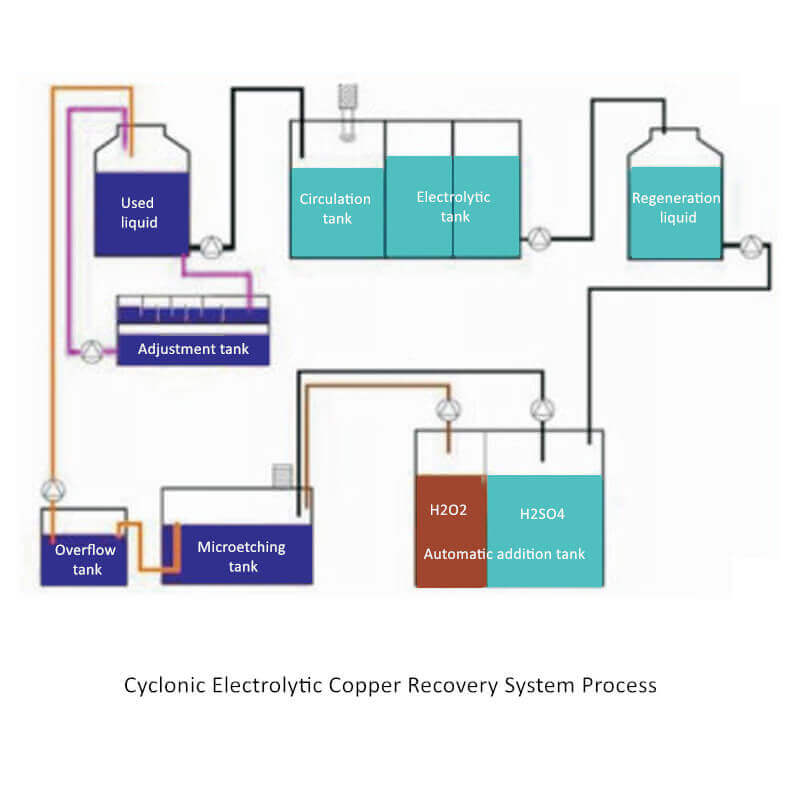

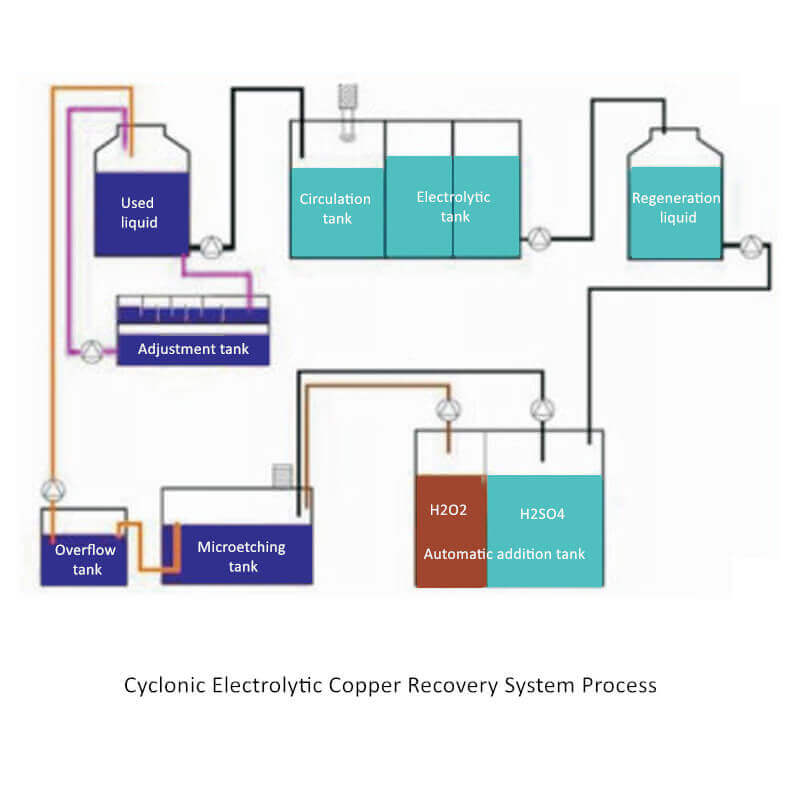

Cyclonic Electrolytic Copper Recovery System Process

The cyclonic electrolytic copper recovery system is an efficient and environmentally friendly metal recovery technology. Through its unique operation and efficient purification capability, it plays an important role in the production of copper electrolysis purification, which not only improves the metal recovery rate, but also effectively reduces environmental pollution, and it is an important part of modern metal recovery and purification technology.

Cyclonic Electrolytic Copper Recovery System Process

Cyclonic electrolytic copper recovery system uses two direct electrolysis methods, the hydrogen peroxide in the waste liquid is cracked by electrolysis first, and then into the electrolytic cell or cyclonic electrolytic tank. After electrolysis of copper by adding a small amount of agents, the micro etching solution can be effectively recovered and recycled.

Technical Features

The machine avoids the traditional electrolytic process by a variety of factors (ion concentration, precipitation potential, concentration polarization, over potential, PH(value), the low concentration of solution for efficient, high purity electrolytic extraction, metal recovery can reach ppm level. Cathode copper can reach 99.99%. Solution closed-circuit circulation, effectively prevent electrolytic exhaust from polluting the environment, modular and portable device, easy to expand or transfer, easy to operate.

Technical Parameters

| Model | Waste Liquid Treatment Capacity (Tons/Month) | Electricity Load (kW) | Copper Production Capacity (Tons/Month) | Occupied Area(m2) |

| YZ-XLDJ50 | 50 | 20-30 | 1.0 | 30-40 |

| YZ-XLDJ100 | 100 | 40-50 | 2.0 | 50-60 |

| YZ-XLDJ200 | 200 | 70-80 | 4.0 | 80-100 |