Big Differences in Water Flow Movement: Symmetrical "Swing" vs. Asymmetrical "Fast Rise, Slow Fall"

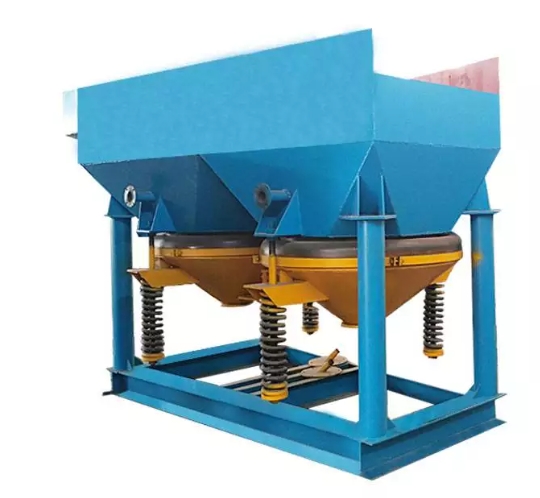

In mineral processing at mines, jigs separate minerals of different densities by the up-and-down movement of water. The core difference between diaphragm jigs and sawtooth wave jigs lies in how the water moves. Traditional diaphragm jigs have water flowing up and down in a symmetrical way, similar to a pendulum swing — the speed and time of the water moving upward are roughly the same as those when moving downward. This leaves a relatively fixed "activity space" for mineral stratification, making it hard to separate minerals of different particle sizes clearly. However, sawtooth wave jigs are different. They use a special mechanical structure to make the water flow in a "fast rise, slow fall" pattern: the time for the water to rush upward only accounts for 1/3 to 1/4 of the cycle, while the time for it to fall downward takes up 2/3 to 3/4. This "quick rush and slow fall" of water loosens the mineral layer more, allowing minerals of different densities to be separated more clearly.

Mineral Processing Performance and Costs: Higher Recovery Rate, Less Water Consumption

The performance gap between the two types of machines is obvious in practical use. Sawtooth wave jigs perform particularly well when processing fine-grained minerals. For example, in the gold mine in Yuanyang, Yunnan Province, the purity of gold separated by sawtooth wave jigs can exceed 80%, and it can be directly smelted after simple processing. Compared with diaphragm jigs, the recovery rate of minerals such as tin, tungsten, lead, and zinc is increased by 3% to 5.5% respectively. Moreover, sawtooth wave jigs are more water-efficient. Due to their more reasonable water flow design, there is no need to add extra water, reducing water consumption by 30% to 40%. At the same time, they can process more minerals in the same-sized area, resulting in higher efficiency.

Which One to Choose? It Depends on the Mine's Actual Needs

It doesn't mean that sawtooth wave jigs are definitely better; the key depends on the mine's needs. If you are processing common non-ferrous metals, have no particularly high requirements for precision, and are engaged in large-scale production, traditional diaphragm jigs are sufficient — they have mature and stable technology. However, if you have special needs, such as processing coarse-grained barite or manganese ore with a maximum diameter of 60mm, or separating alluvial gold, fine-grained tungsten-tin ore, or even recovering metals from smelting slag, sawtooth wave jigs are more suitable. Additionally, their parts can be flexibly assembled, and their speed can be adjusted freely, making them convenient for small and medium-sized mines. Nowadays, many mines that pursue environmental protection are willing to choose them.