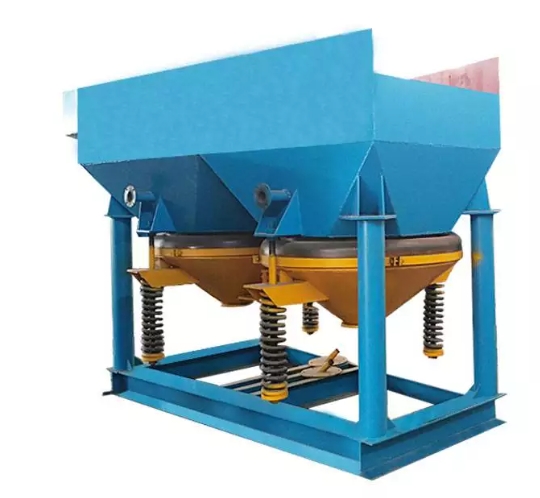

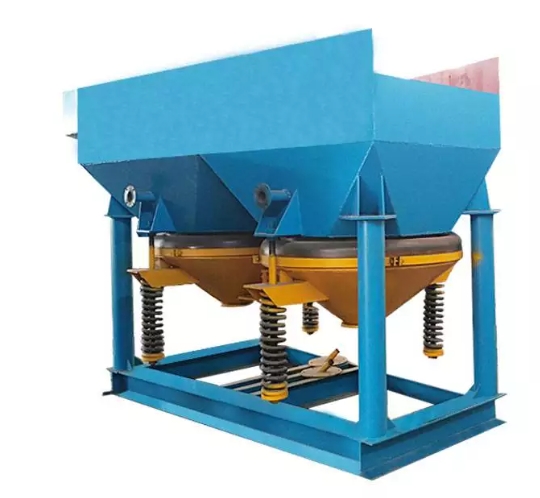

The cross-section of a rectangular jigging chamber is a standard rectangle, with its width and height remaining consistent along the jigging direction. The internal space features a "straight-tube" structure, ensuring relatively uniform ore distribution inside the chamber. However, the effective separation volume of a single rectangular chamber is fixed, making it difficult to increase processing capacity through space optimization.

In contrast, a trapezoidal jigging chamber has a trapezoidal cross-section. Typically, its width gradually increases or height gradually rises along the ore movement direction (from the feed end to the discharge end), forming an "expanded" space. This design reduces ore congestion during separation: the narrow feed end ensures uniform initial ore distribution, while the wide discharge end provides greater buffer space for "density-based separation" after ore stratification. With the same equipment size, the actual processing capacity of a trapezoidal jigging chamber is 15%-30% higher than that of a rectangular one, making it more suitable for large-scale roughing or intermediate separation operations.

The core of jigging separation lies in "water pulsation + density stratification," and the shape of the jigging chamber directly affects water flow distribution and ore force bearing. Due to its uniform internal space, a rectangular jigging chamber tends to form a "flat-pushing" flow field during water pulsation. The difference in water flow velocity between the area near the chamber wall and the center is small, but the vertical stratification force of ore mainly relies on the up-and-down pulsation of water flow. This results in slow stratification speed, and high-density minerals are prone to "wall adhesion and retention," which affects separation purity.

For a trapezoidal jigging chamber, the gradual change in space causes water flow velocity to decrease gradually from the narrow end to the wide end, forming a "decelerating" flow field: the higher water flow velocity in the narrow feed end can quickly suspend the ore; the reduced water flow velocity in the wide discharge end allows the ore to settle more fully according to density—high-density minerals (e.g., metal ores) quickly sink to the bottom of the chamber, while low-density minerals (e.g., gangue) float up with the water flow. The stratification accuracy of trapezoidal chambers is 20%-25% higher than that of rectangular ones, making them particularly suitable for separating ores with small density differences.

The stability of jig discharge directly affects separation indicators. For rectangular jigging chambers, the fixed width requires the discharge port to fully match the chamber width. If there are fluctuations in ore particle size (e.g., sudden appearance of large ore lumps), it is easy to cause blockage of the discharge port or "coarse particle loss" (high-density coarse-grained minerals are discharged with tailings). Additionally, the "pushing distance" of ore at the chamber bottom during discharge is fixed, and some ore that has not been fully stratified may be forced to discharge, reducing the recovery rate.

Trapezoidal jigging chambers have a wider discharge end, so their discharge ports can be designed as "wide adjustable type." This not only accommodates ores with fluctuating particle sizes but also allows for adjusting the discharge speed to provide a longer "secondary stratification" distance for ore at the chamber bottom. Meanwhile, the inclination angle of the trapezoidal chamber bottom (usually coordinated with the gradual width change direction) can assist ore movement toward the discharge port, reducing the risk of blockage. Trapezoidal chambers have stronger operational adaptability and are especially suitable for processing ores with a wide particle size range (e.g., 5-50mm).